Projects Engineered

Trusted Partners

Who We Are

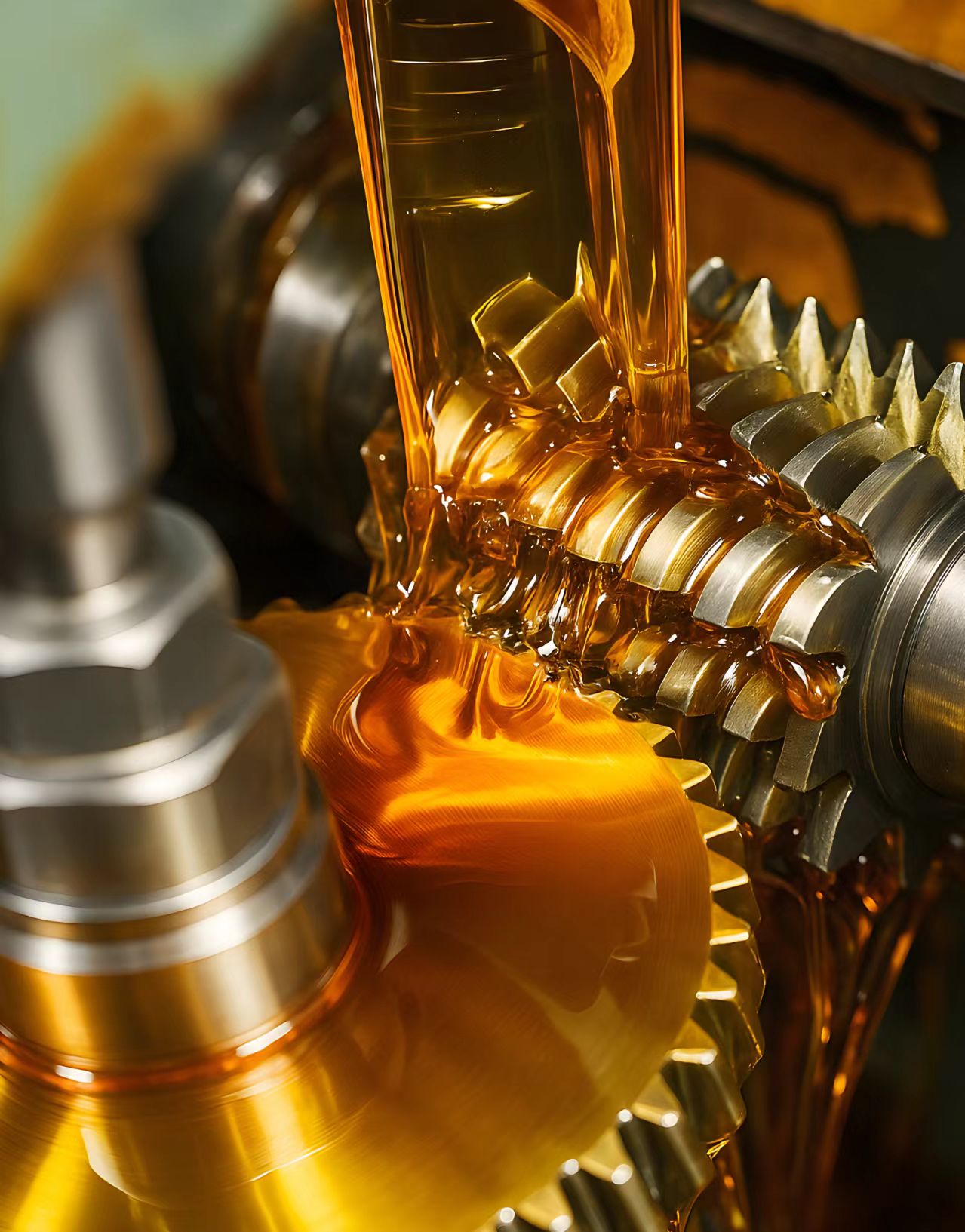

We Are Ready For Efficient Lubrication. All We Need Is To Boost Your Operations!

It’s not just lubrication – it’s operational fuel. Our systems cut downtime by 30%+, extend equipment life by years, and turn maintenance costs into savings. With Bailang, efficiency isn’t a goal – it’s a guarantee.

Tell us your industry, equipment, and challenges – we’ll design a system that works as hard as you do.

30+ years expertise in tailoring lubrication for industrial gears, rails & joints

Cost Efficiency

Reduce maintenance downtime by 30%+ with our smart lubrication systems

Custom Solutions

From robotics to construction machinery – bespoke designs for every need

Quality Certified

ISO 9001:2000 approved, ensuring lifelong reliability in harsh conditions

Our Besr Services

A Leading Supplier Of Industrial Lubrication Systems & Components

CNC Machine Tools Lubrication

Precision lubrication for high-speed spindles, rails, and the tool changers – We ensuring 24/7 accuracy and minimal wear.

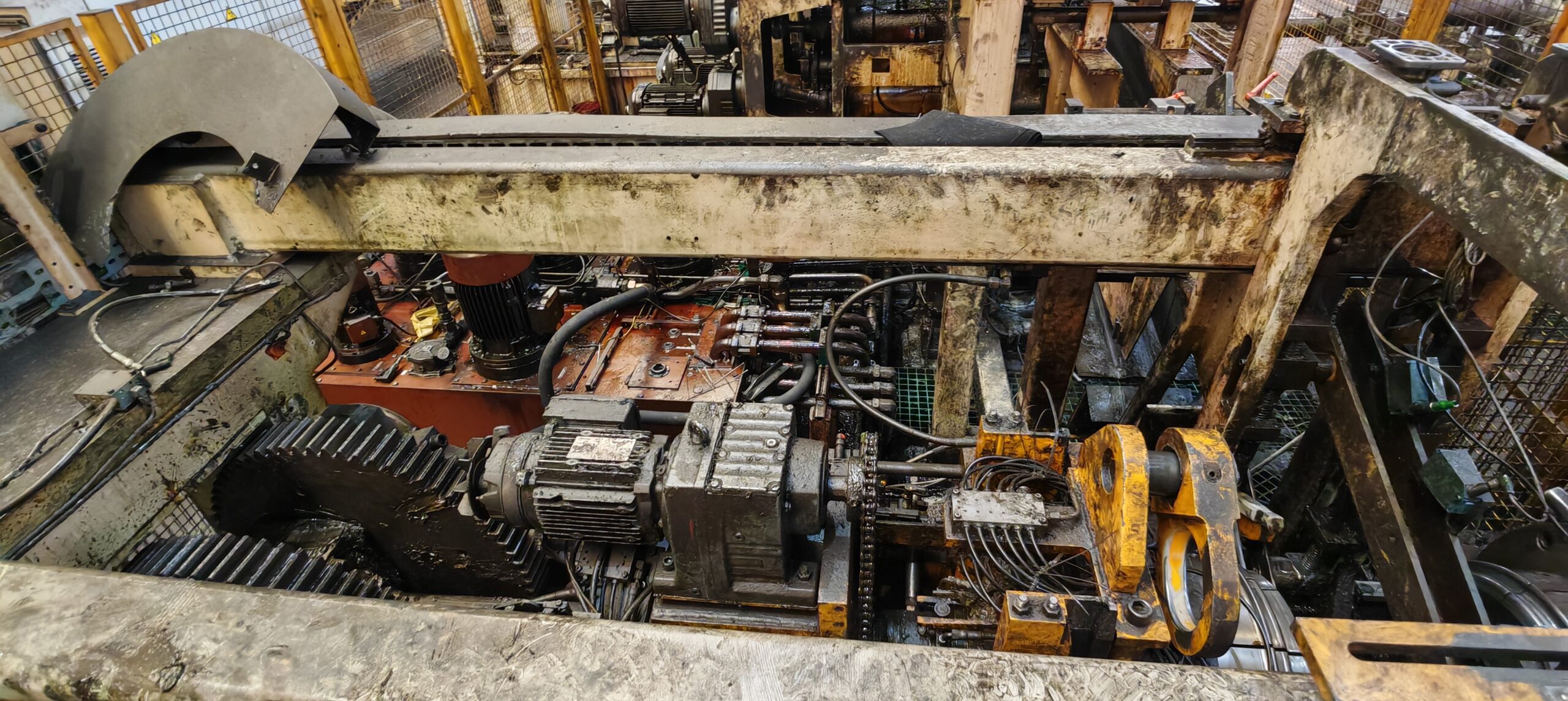

Construction Machinery Lubrication

Heavy-duty lubrication systems for excavators, cranes, and loaders – built to withstand dust, shocks, and extreme pressures.

Robot Joint Lubrication

Micro-precision lubrication for robotic arms and joints – enabling smooth movement, repeatability, and long service life.

Textile Machinery Lubrication

Low-noise, low-maintenance lubrication for spinning frames, looms, and knitting machines – reducing downtime in high-speed production.

Our FAQs

We Are The Best Lubrication Products & Solutions Provider

What Is A One-stop Lubrication System Solution?

Ningbo Bailang provides integrated lubrication solutions, covering system design, component supply, installation guidance, and after-sales support. Our one-stop service ensures seamless operation for your industrial equipment.

Which Industries Do Your Lubrication Systems Serve?

Our systems are tailored for diverse industries:

- CNC Machining Equipment (e.g., spindle, guideway lubrication)

- Textile Manufacturing Machinery

- Construction & Heavy Machinery

- Industrial Robotics (e.g., robotic arm lubrication)

What Are The Key Features Of Progressive Grease Lubrication?

Progressive grease systems ensure precise, sequential lubrication for multi-point industrial equipment. Ideal for heavy-load scenarios (e.g., port cranes), they reduce wear and extend maintenance intervals.

How Does Thin Oil Lubrication Benefit High-speed Machinery?

Thin oil lubrication provides efficient cooling and friction reduction for high-speed equipment (e.g., CNC spindles). It maintains stable operation under extreme conditions, enhancing precision and productivity.