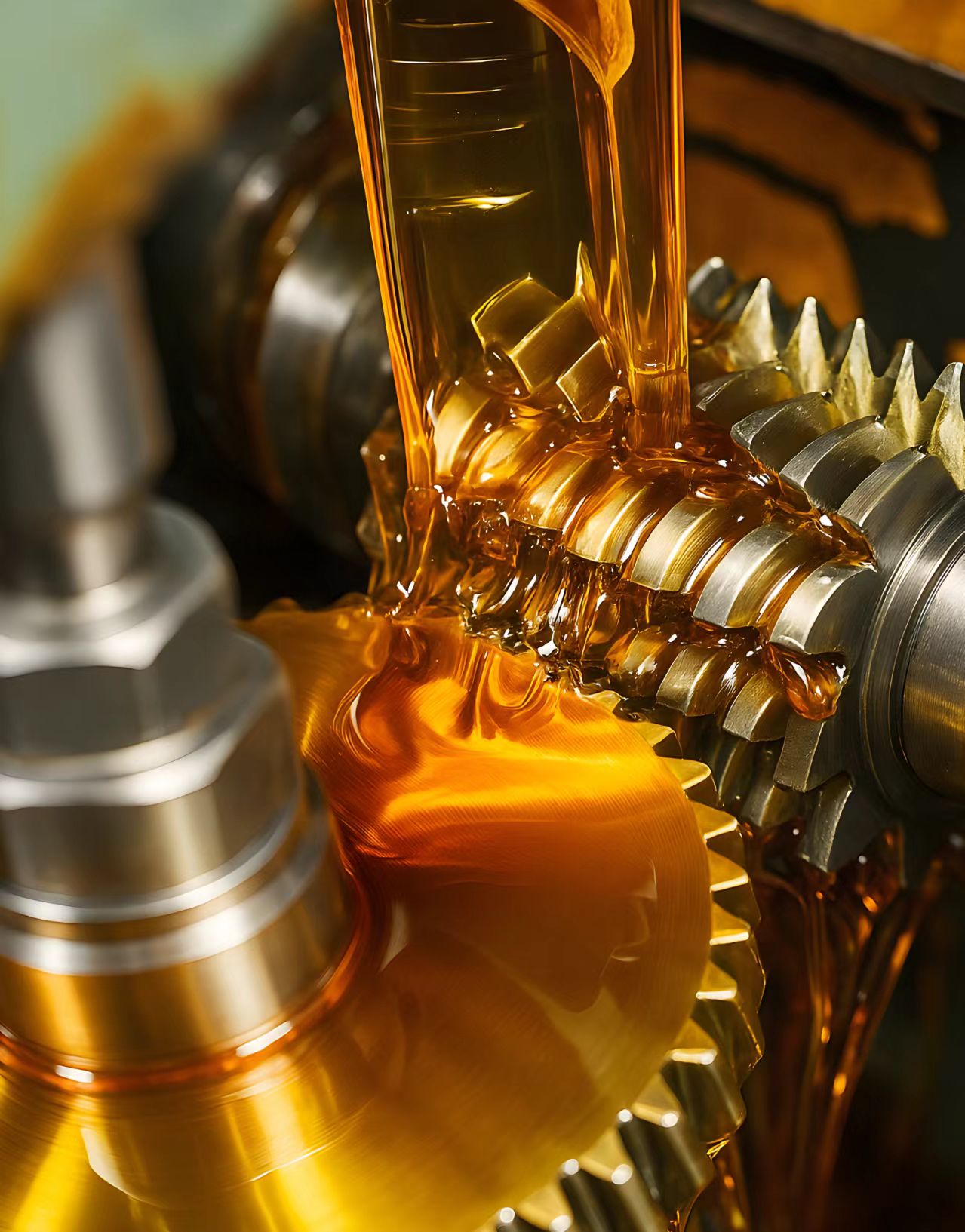

30+ years expertise in tailoring lubrication for industrial gears, rails & joints

Cost Efficiency

Reduce maintenance downtime by 30%+ with our smart lubrication systems

Custom Solutions

From robotics to construction machinery – bespoke designs for every need

Quality Certified

ISO 9001:2000 approved, ensuring lifelong reliability in harsh conditions

Projects Engineered

Trusted Partners

Who We Are

We Are Ready For Efficient Lubrication. All We Need Is To Boost Your Operations!

It’s not just lubrication – it’s operational fuel. Our systems cut downtime by 30%+, extend equipment life by years, and turn maintenance costs into savings. With Bailang, efficiency isn’t a goal – it’s a guarantee.

Tell us your industry, equipment, and challenges – we’ll design a system that works as hard as you do.

Our Besr Services

A Leading Supplier Of Industrial Lubrication Systems & Components

CNC Machine Tools Lubrication

Precision lubrication for high-speed spindles, rails, and the tool changers – We ensuring 24/7 accuracy and minimal wear.

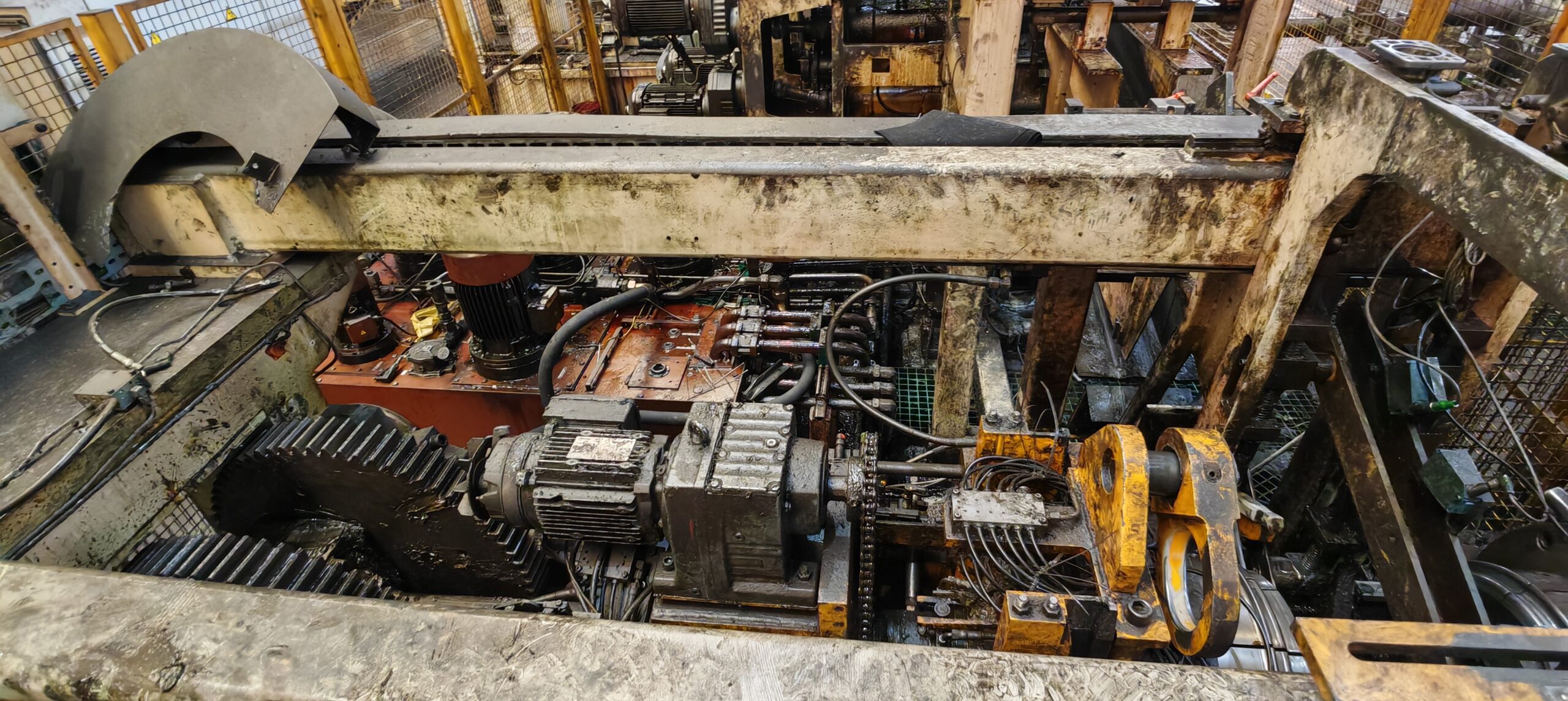

Construction Machinery Lubrication

Heavy-duty lubrication systems for excavators, cranes, and loaders – built to withstand dust, shocks, and extreme pressures.

Robot Joint Lubrication

Micro-precision lubrication for robotic arms and joints – enabling smooth movement, repeatability, and long service life.

Textile Machinery Lubrication

Low-noise, low-maintenance lubrication for spinning frames, looms, and knitting machines – reducing downtime in high-speed production.

On Sale Item

Top - Selling Lubrication System Components

Our FAQs

We Are The Best Lubrication Products & Solutions Provider

What Is A One-stop Lubrication System Solution?

Ningbo Bailang provides integrated lubrication solutions, covering system design, component supply, installation guidance, and after-sales support. Our one-stop service ensures seamless operation for your industrial equipment.

Which Industries Do Your Lubrication Systems Serve?

Our systems are tailored for diverse industries:

- CNC Machining Equipment (e.g., spindle, guideway lubrication)

- Textile Manufacturing Machinery

- Construction & Heavy Machinery

- Industrial Robotics (e.g., robotic arm lubrication)

What Are The Key Features Of Progressive Grease Lubrication?

Progressive grease systems ensure precise, sequential lubrication for multi-point industrial equipment. Ideal for heavy-load scenarios (e.g., port cranes), they reduce wear and extend maintenance intervals.

How Does Thin Oil Lubrication Benefit High-speed Machinery?

Thin oil lubrication provides efficient cooling and friction reduction for high-speed equipment (e.g., CNC spindles). It maintains stable operation under extreme conditions, enhancing precision and productivity.

Contact Us

Providing Lasting Value to Clients Through Professional Lubrication Solutions

We have been deeply engaged in the industrial lubrication components industry since 2015. By continuously optimizing product performance (such as improving lubrication precision and system stability) and providing tailored solutions, we help clients reduce equipment maintenance costs and improve production efficiency.

Precision Lubrication

Customized Solutions

Reliable Service

Request A Quote